In the present global scenario, there is a slight bend towards getting production processes in one’s own country. This is true for the maximum number of companies and especially for those that utilize plasma cutting tables. Most companies use metal fabrication as a part of their production process. Having a CNC plasma system in house helps to reduce the outsourcing expenses. It allows the metal fabrication to cut across the metal parts thereby providing greater flexibility to the entire production process. Hence the industrial units are trying to figure out ways of maximizing its utility. However there are 5 industrial units where plasma cutting tables has an important role to play.

Let’s Have A Look At Those:

- The Transportation Sector- Whether it’s the automobile sector or the manufacture of tractors, most of these industries require the cutting of customised metal parts. CNC plasma cutting sector is used for a variety of purposes in this field. It is used to fabricate lighting brackets and has an essential part to play in the manufacturing of storage boxes. They get most of their customers from the public sector services, who demand for a lot of customization on their vehicles.

- HVAC- These companies have a good knowledge about the advantages of the plasma cutting table. Owning a plasma cutting system helps to minimise a lot of troubles. This whole system engenders the reproduction of parts that is really needed for such commercial industries. This helps to cut down the production cost effectively. The software partner of HVAC is Shop Data systems. A good number of cutting applications are offered by this company.

- Metal Art and Customs Displays sector- Metal artists are generally very fond of the CNC plasma cutting system. As it allows them to design freely and cut the sheet of metal accordingly. This saves a lot of labour as they do not have to do the same by hand. Most of the artists who use the CNC plasma cutting table are experienced artists. They have a lot of dependable resources at hand to sell off their artwork. The custom displays companies also make use of plasma cutters. It includes a number of products such as the retail merchandising display field.

- The construction sector- The construction sector reaps the maximum benefits out of the plasma cutting table. It is used for cutting a number of things such as brackets, parts for fencing and the others. The plasma cutting system is of paramount importance in this sector. It can be used to cut water slides and also for the construction of electrical boxes used in the mining industry. There are a lot of ways by which the plasma cutting system can improve the efficiency of a company.

Tips To Remember While Procuring A Plasma Cutting Table

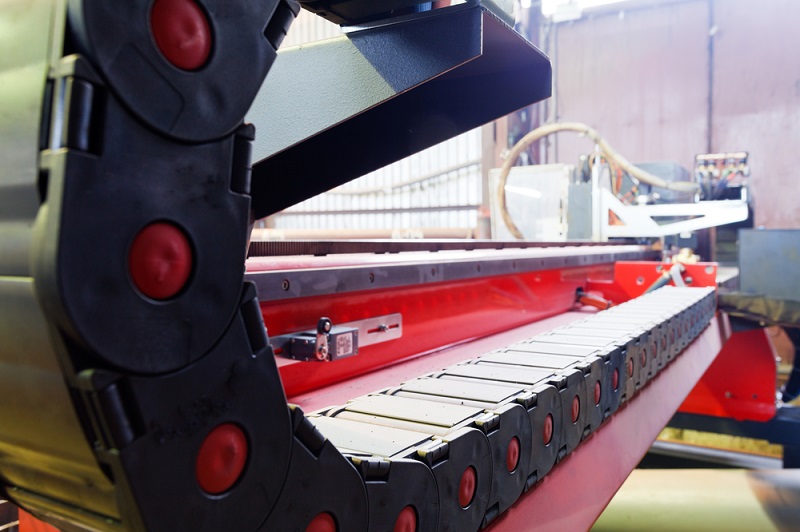

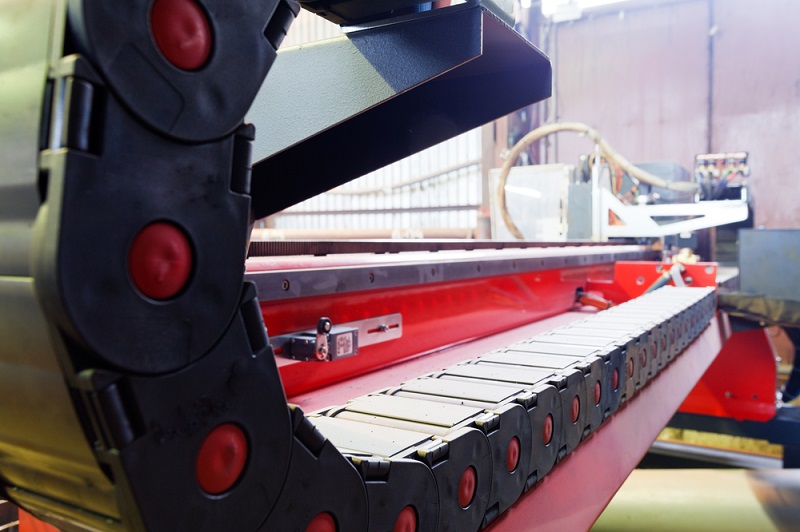

- The very first step towards choosing the plasma cutting table banks upon the question whether one is going to use it mechanically or on a table. Some plasma tables are capable of doing both while others can perform only one function. It should be a reliable product that efficiently reduces the operation cost of the production company. One must also keep in mind the quality and capacity of cutting.

- The plasma table should have a CNC interface and an internal voltage divider. As this has the capability of increasing its work efficiency. The cutting capacity of the table needs to be looked out for as the thickness of the material to be cut might vary.

- The plasma cutting table should have smooth and clean edges so that one does not have to spend too much time in additional work.